Laboratories

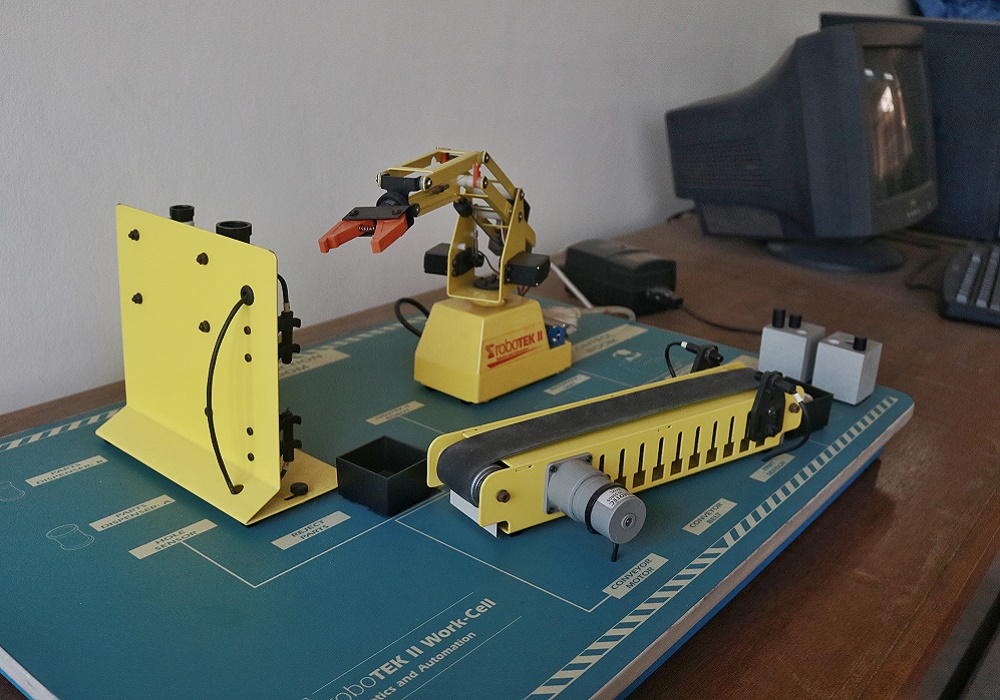

Department of IPE is rich in lab facilities to make the students familiar with the real world application by assisting them to connect theoretical knowledge with practical experience. From learning how to run Injection Molding machine to application of screw conveyors through advanced measurement techniques with Co-ordinate Measuring Machine, the students get the perfect opportunity to gather the latest knowledge in production and manufacturing engineering. They also get to familiarize with the automation techniques like PLC and Robot. Again they learn the latest industrial simulation techniques and CAD softwares like, MATLAB/Simulink, ANSYS, Arena, AutoCAD, SolidWorks, CATIA etc. It's not just the design, they also learn the practical use which makes them ready not less than any experts in the job field where the excellence is the only thing that matters.

Machine Tool Lab

CAD/CAM Lab

Measurement Instrumentation and Control Lab

Product Design Lab

Material Handling Lab

Simulation & Optimization Lab

A variety of optimization and simulation software like MATLAB, ARENA, ANSYS, COMSOL, Materials Studio etc are taught in this laboratory with the help of modern computers and high speed internet connections to make the students familiar with the importance of simulation in the industrial sectors. The lab also incorporates a Projet 260C 3D printer.

Production Process Lab

This laboratory is equipped with microscopes and different testing machines such as- Fatigue Testing Machine, Micro Hardness Tester, Universal Testing Machine, Tensile Testing Machine, Impact Testing Machine to serve the purpose of joint test with computer control to make the students acquainted with different welding joints and their strengths and to familiarize them with the microstructure of these welded joints.

Metrology Lab

The Metrology Laboratory is set with the most advanced prototypes and measuring equipments like Different types of gauges and plugs, Pitchometer, Sine Bar, Bevel Protractor, Propeller, DB Meter, Lux Meter, Super Micrometer etc. to make the students connected with different measuring instruments and measurement processes.